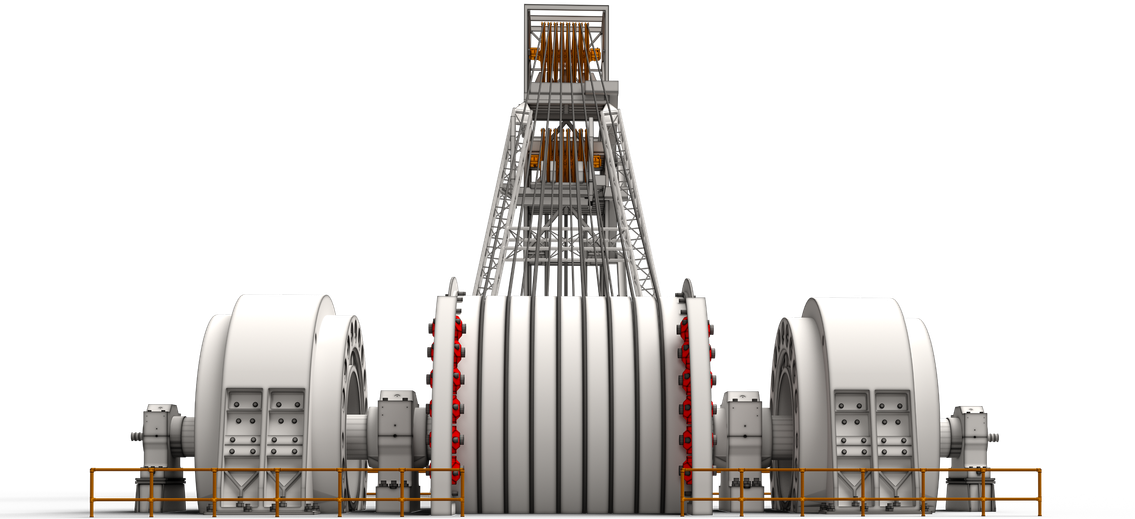

One hoisting system. One responsibility.

INCO designs and integrates complete hoisting solutions and takes responsibility for system behaviour from shaft sinking to production.

Why customers choose INCO

Single system responsibility with no fragmented interfaces

One partner. One system.

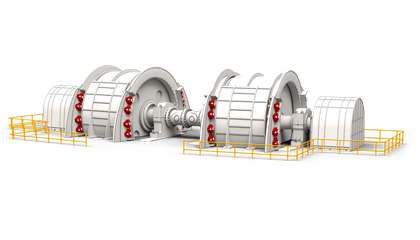

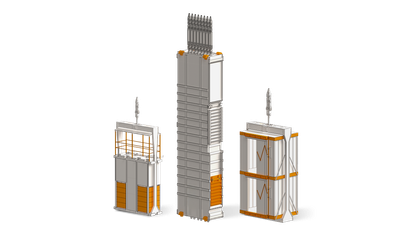

One integrated hoisting system designed and built as one engineering flow from surface to shaft bottom.

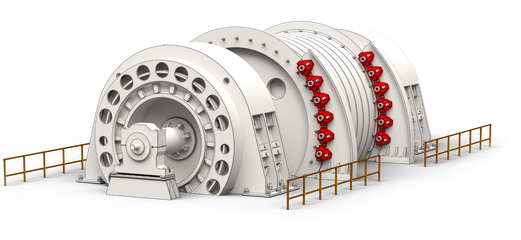

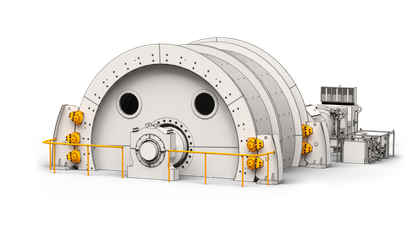

Mechanical

engineering

Engineered hoisting elements manufactured with system-level precision.

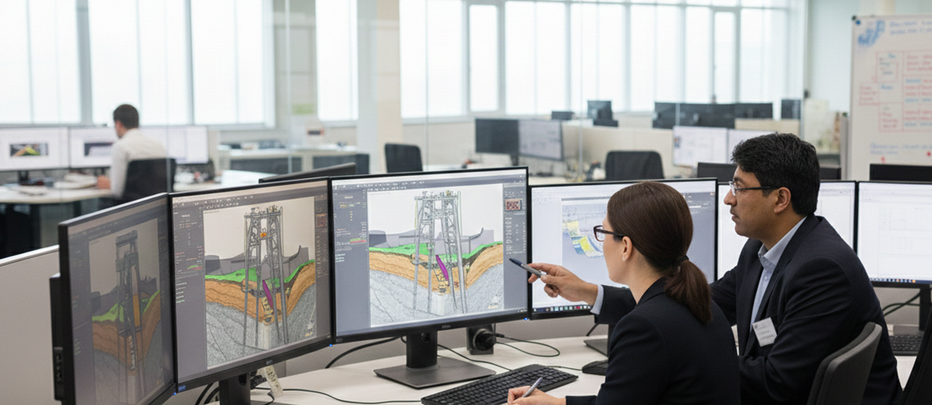

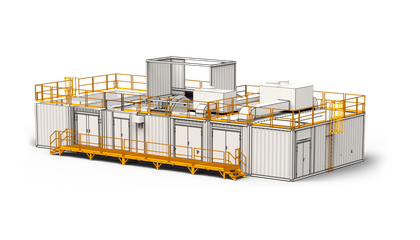

Automation

Automation engineered as part of the hoisting system

Shaft Hoist Doctor

by INCO

Real-time system monitoring and diagnostics

Lifecycle responsibility and long-term support

Engineering support beyond commissioning

Our references

Over 600 shaft hoisting projects delivered under single OEM responsibility.

Looking for similar projects?

Engineering under European

and International standards

and International standards

Our hoisting systems comply with EU machinery directives and mining safety regulations.

Quality, safety, environment

Certified according to ISO 9001, 14001, 45001.Electrical and automation safety

Control, automation and drive systems comply with EN and IEC standards. Explosion-proof solutions where required.Engineering

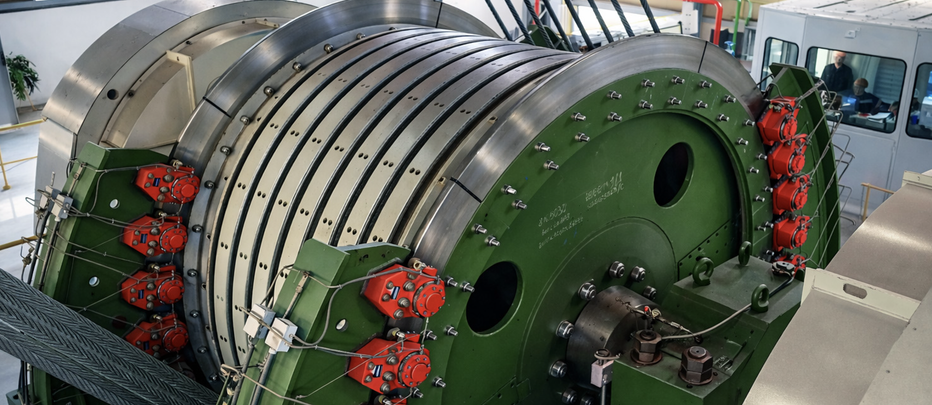

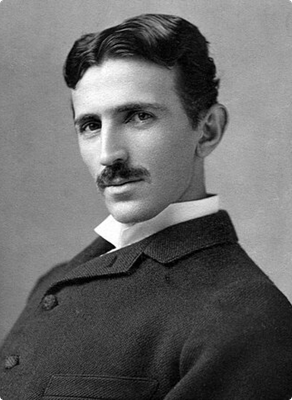

tradition since

INCO continues the engineering heritage of Prague, rooted in the foundations of ČKD.

This heritage connects us to major European engineering milestones:

early mechanical workshops that shaped Central European industry

innovations of Emil Kolben, collaborator of Nikola Tesla

industrial development that later gave rise to globally recognised engineering brands including Škoda

Today, INCO carries this legacy forward with modern hoisting systems engineered for heavy-duty mining around the world.

ESG and responsible engineering

INCO supports responsible mining through safe system design, European manufacturing and long-term lifecycle support.

Have a project in mind?

How can we assist you to increase your mines production? Let’s talk.